In many situations in life you can go cheap, but you may pay for it in the end. This is especially true for dust collector hood designs. Small changes in hood designs often yield big results – especially in performance and total cost of operation.

Savvy managers know their greatest asset is their people, so it’s no surprise that worker comfort is a top priority for successful businesses. The ACGIH – Industrial Ventilation, A Manual of Recommended Practice for Design is in its 28th edition and is considered by many to be the standard by which dust collection solutions should be measured. It incorporates industrial hygiene best practices and is all about improving the breathing zone of operators and staff in facilities. This manual offers guidance for hooding options and presents a good, better, best case strategy for many hood configurations.

When starting out on hood design, it is helpful to also consider the importance of concerns beyond improving workspace air quality. The possible combustible nature of dusts or their possible toxicity may influence hooding and system design. Your facility could be at serious risk if certain cleanliness standards are not met. Beyond the impact on worker conditions, hefty fines could be leveled if your facility is found to be out of compliance.

In addition to workplace air quality, managers often have to balance two significant considerations in any business – product or work quality and operational cost. Sometimes savings are not obvious, such as the potential for improved hood design to reduce capital costs in equipment such as fans. Given that hood design can be a critical consideration, let’s explore some different options.

COMMON HOOD DESIGNS

If you are unable to enclose your process, then you may need an external hood located close to the operation in order to control dusts generated during operation. The five basic external hood types are listed in their order of increasing effectiveness, but also in their increasing fabrication cost. However, initial fabrication costs for hoods may be quickly offset when you compare related considerations such as:

- Improvements in plant cleanliness and reduced downtime to manufacture your product,

- Possible savings in corresponding smaller ducts, smaller collectors, and smaller fans, and

- With smaller energy and air volume requirements, you can see lower fan horsepower, which means reductions in related utility costs.

1 – RAW EDGE HOOD

The raw edge hood represents the most common and least expensive of all hood configurations. It is just an open duct which terminates near the dust generation point. Hood design just doesn’t get much simpler than this approach.

The raw edge hood represents the most common and least expensive of all hood configurations. It is just an open duct which terminates near the dust generation point. Hood design just doesn’t get much simpler than this approach.

Raw edge hoods, while very simple to produce, provide the poorest performance in collecting contaminants at the point of generation. This hood configuration pulls air not only from in front of the duct opening, but, unfortunately, also from behind the hood opening, which makes it inefficient. This configuration also creates a high degree of turbulence that can contribute to increased energy losses and a potentially larger fan. This hood configuration option is less than optimal from a total cost of operation perspective.

2 – FLANGED HOOD

The flanged hood is relatively simple with a low fabrication cost, and this option improves on the raw edge design with the addition of a flange. The flanged hood provides better performance because the air/energy used to collect the dust in limited to the zone in front of the open duct.

The flanged hood is relatively simple with a low fabrication cost, and this option improves on the raw edge design with the addition of a flange. The flanged hood provides better performance because the air/energy used to collect the dust in limited to the zone in front of the open duct.

The addition of a flange to a hood design focuses the hood’s performance and reduces the air volume required to maintain facility cleanliness. It also improves the air quality in your employees’ work environment. Flanges don’t have to be round if square or even triangular work better in a situation, as long as the shape focuses air entry into the hood from the front. When it comes to flanges, something really is better than nothing. Flanged hoods may still involve excess turbulence, so let’s explore design improvements to see if we can help reduce that.

3 – TAPERED HOOD

A tapered hood offers our next improvement in hood performance. Consider a round duct with a rectangular flange. If we fold the flange edges forward and connect them at their sides, we can create a tapered funnel that still directs air into the duct. This tapered funnel eases the air into the hood more gradually than a raw or flanged entry, reducing the turbulence created as air enters the duct at the back of the hood.

A tapered hood offers our next improvement in hood performance. Consider a round duct with a rectangular flange. If we fold the flange edges forward and connect them at their sides, we can create a tapered funnel that still directs air into the duct. This tapered funnel eases the air into the hood more gradually than a raw or flanged entry, reducing the turbulence created as air enters the duct at the back of the hood.

This more gradual transition saves energy and decreases the operating cost of the fan, offering long term savings for a minor increase in hood fabrication costs. The reintroduction of a flange at the face of the hood once again focuses the effectiveness of the hood and reduces the total air volume. It also creates the same savings opportunities in capital equipment in terms of smaller size ducts, smaller collectors, and lower fan horsepower.

4 – CONICAL HOOD

A conical hood transitions from a round, rather than rectangular, hood opening. It also takes your hood design one step further to improved performance. This approach improves hood performance by further reducing the turbulence generated as air enters the duct at that back of the hood. It also reduces the energy required and saves on fan horsepower.

A conical hood transitions from a round, rather than rectangular, hood opening. It also takes your hood design one step further to improved performance. This approach improves hood performance by further reducing the turbulence generated as air enters the duct at that back of the hood. It also reduces the energy required and saves on fan horsepower.

Again, the addition of a flange at the face of the hood will reduce the air volume needed to control dust, and it offers the savings mentioned earlier in terms of capital costs such as ducts, collectors, or fan horsepower. As you can see, most of these are relatively simple fabrications in sheet metal that can be added to any open duct.

5 – BELL MOUTH HOOD

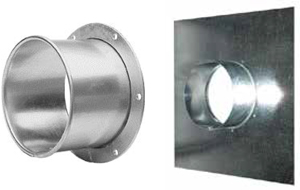

The bell mouth hood offers what is probably the pinnacle of external hood performance. It combines the benefits offered by flanged hoods with a very smooth transition from the flange to the duct entry. This smooth transition minimizes turbulence as air enters the duct. It offers both the airflow reduction performance of a flange and the low turbulence of the spun bowl entry profile and is the most effective external hood design available.

The bell mouth hood offers what is probably the pinnacle of external hood performance. It combines the benefits offered by flanged hoods with a very smooth transition from the flange to the duct entry. This smooth transition minimizes turbulence as air enters the duct. It offers both the airflow reduction performance of a flange and the low turbulence of the spun bowl entry profile and is the most effective external hood design available.

Of course, this increased performance doesn’t come without some investment. Since this hood inlet typically involves a spun cone to produce the smooth inlet fabrication, costs are higher.

OTHER FACTORS TO CONSIDER

HOOD POSITION

So we’ve talked about different hood configurations and shapes, but let’s not overlook another critical question: Where should the hood be located relative to the source generating the dust? You could have chosen the most expensive and highest performance hood, but if it’s not properly positioned, you’re collecting a lot of air and very little dust. The position of the hood close to the dust generation point is part of the description for source collection. For the system to achieve effective dust management, the hood needs to be as close as possible to the dust generation point. This reality may help explain why proximity is so important. Consider the following situations:

EXAMPLE 1: A 4-inch diameter raw edged hood is located one foot away from the dust source and needs to generate a capture velocity of 100 ft/min at the dust generation position to control the dust. To estimate the required air volume to produce that velocity, we use the equation from the Industrial Ventilation Manual. Q=(10X2 + A) V

- The distance away from the source (x) is one foot,

- The cross sectional area of the duct (A) is 0.087 square feet for a 4-inch duct, and

- Total airflow required is (Q) = [10(1ft)2 + (0.087 ft2]100 ft/min = 1,009 cubic feet per minute.

Let’s take a quick look at a two examples where we only change the distance (x) by moving the hood so it is only six inches from the dust generation point.

EXAMPLE 2: The 4-inch diameter raw edged hood is now located six inches (0.5 feet) from the dust source and still needs to generate a capture velocity of 100 ft/min at the dust generation position to control the dust. To estimate the required air volume, we again use the same equation from the Industrial Ventilation Manual. Q=(10X2 + A) V

- The distance away from the source (x) is now 0.5 feet,

- The cross sectional area of the duct (A) is still 0.087 square feet, and

- Total airflow required is (Q) = [10(0.5ft)2 + (0.087 ft2]100 ft/min = 259 cubic feet per minute.

As you can see, a change in distance (x) has a dramatic effect on the total airflow required. In this instance, and in most other instances, the air volume required is reduced by a factor of four when the distance is cut in half. That’s a pretty significant change. Consider what that six inches of additional duct might cost compared to a collector or fan

that is four times larger than necessary. And don’t forget you can run smaller ducts because less air is required, resulting in additional cost savings.

But let’s get down to that critical design element: total cost of ownership. Hopefully, you can now see how better hood design can help reduce operational costs by reducing the total air volume required to manage your dusts. This means you can consider smaller ducts, smaller collectors, and smaller fans. So you’ve just saved dollars on three big capital ticket items.

Now consider the costs of running the fan and collector. With less turbulence and lower total air volumes, you should see reductions in the horsepower needed to run the system. And if you exhaust less air from your facility, there is lower demand for make-up air, reducing the load on your HVAC system. And what’s the life of those products?

Ten years? Twenty years? How will that affect your annual electric and compressed air costs? So you can see how small changes in simple system components can yield big results in your cost of ownership. From improved facility and employee work space conditions to total cost of equipment ownership, best practices in hood design should be a critical consideration in your design. Small changes can mean big results, and that’s often EXACTLY WHAT YOU NEED.