Many industrial dust collectors use compressed air to clean and extend the life of their filters. This is typically accomplished using short pulses of compressed air inside of the individual bag filters or cartridge filters in order to blow or knock the dust off of the outside of the filter.

Those responsible for the operation of industrial dust collectors need to manage the compressed air supplied to the dust collector to ensure proper performance while controlling operational costs. Doing so helps reduce costly compressed air consumption, maximizes dust collector airflow performance, and reduces collector maintenance and down-time costs.

CLEAN-ON-DEMAND VS. CONTINUOUS CLEANING

The first tip for controlling compressed air consumption for industrial dust collectors is to invest the extra money for quality on-demand-cleaning controls when buying your industrial dust collector.

Many collectors come standard with a control panel that continuously and automatically pulses filters with compressed air every 10 or 15 seconds – whether the filters need to be cleaned or not. This adds unnecessary costs for multiple reasons.

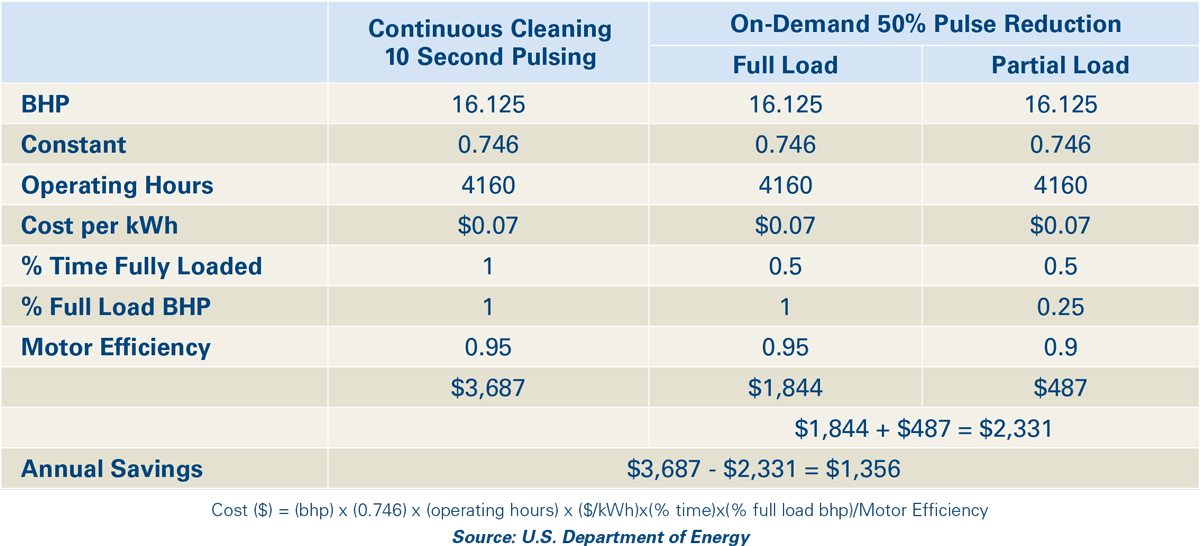

First, in most situations with continuous cleaning, more compressed air is being consumed than is needed to maintain stable collector operation. Depending on how a collector was initially sized and the volume of dust the collector is handling, it is likely that the frequency of cleaning (and the compressed air consumption) can be cut in half. In the case of a 50,000 cfm dust collector, a 50% reduction in pulsing could result in an annualized savings of over $1,300. This calculation assumes the collector is running two 8-hour shifts per day, 5 days per week. (See table below). This kind of savings could easily offset the investment of an on-demand controller in a month or two.

The second reason continuous cleaning increases cost is because excess pulse cleaning can fatigue filters which can shorten filter life. Shorter filter life means replacing filters more frequently resulting in higher replacement filter costs, increased labor costs to replace the filters, and increased downtime.

On-demand controllers monitor the airflow resistance across the filters and tubesheet as air passes from the dirty to the clean air side of the collector. This resistance, known as pressure drop or “delta P,” is measured in units of inches or millimeters of water gauge (wg). An on-demand controller is equipped with both a high and a low set point, which are typically adjustable by the operator. The high set point is associated with the pressure drop where filter cleaning is activated. As the filters are then pulse cleaned, the resistance to airflow decreases with a resulting reduction in the measured pressure drop. When the pressure drop falls below the low set point, pulse cleaning of the filters is automatically stopped. Once pulse cleaning is stopped, the filters will again experience a slow increase in pressure drop until the resistance reaches the high set point level where the sequence begins again.

On-demand controllers monitor the airflow resistance across the filters and tubesheet as air passes from the dirty to the clean air side of the collector. This resistance, known as pressure drop or “delta P,” is measured in units of inches or millimeters of water gauge (wg). An on-demand controller is equipped with both a high and a low set point, which are typically adjustable by the operator. The high set point is associated with the pressure drop where filter cleaning is activated. As the filters are then pulse cleaned, the resistance to airflow decreases with a resulting reduction in the measured pressure drop. When the pressure drop falls below the low set point, pulse cleaning of the filters is automatically stopped. Once pulse cleaning is stopped, the filters will again experience a slow increase in pressure drop until the resistance reaches the high set point level where the sequence begins again.

On-demand cleaning allows the operator of the dust collector to adjust both the high and low set points based on the needs of the collector and/or application. Typically, the high set point which begins pulse cleaning will be set at roughly 2.4-4”. Water gauge (wg) and the low set point will be in the 1.5-2” range. As filters experience extended service, the operator may choose to adjust the high and low set points upward to avoid continuous cleaning. This can be repeated until it makes more economic sense to replace the filters, rather than to continue operating against the increased resistance of dirty filters.

As mentioned above, using an on-demand controller is often well worth the investment. The savings in compressed air consumption and improved filter life can typically pay for the controller investment in just a few short months.

CLEAN, DRY COMPRESSED AIR

The second tip on compressed air use for industrial dust collectors is to make sure the compressed air being used to clean the filters is clean and dry. The compressed air should be free of oils, particulate and water. Oils sometimes enter the compressed air from the compressors, since compressors use oil as a lubricant in the compression process. Particulate gets into the compressed air lines either from dust in the air being compressed and/or from rust and debris inside of the compressed air piping. Water in the compressed air line typically occurs as a result of the compression process. Moist ambient air becomes saturated as it is compressed, and cooling the compressed air creates condensation. Oil, dirt, and moisture in compressed air all need to be controlled to optimize the cleaning performance.

Oil in the compressed air used in industrial dust collectors can foul pulse cleaning components such as the solenoids, causing them to stick open or closed. In addition, oils can sometimes react with plastic materials like the diaphragm in the pulse cleaning valves causing them to become stiff or brittle thus shortening their lives. And finally, oils can coat or saturate the actual filters, reducing their permeability, binding dust to their surface, or generally minimizing their effectiveness.

Particulates in the compressed air can create a build-up in compressed air cleaning components, limiting the operation of the solenoids and diaphragm valves.

Lastly, compressed air used for cleaning must be dry. Compressing air can generate a lot of moisture challenges because of the amount of water involved. As an example, consider 20 cfm of compressed air during two 8-hour shifts on a day where it is 90°F with a 70% relative humidity. In this example, 3.2 gallons of matter are going to appear via condensation by the time the compressed air gets to the dust collection if the compressed air is not treated.

Such water can saturate a filter and lead to:

- Dusts becoming wet and sticking to the filter media, which reduces the effectiveness of pulse cleaning and results in higher pressure drops and ultimately shorter filter life. Higher pressure drop may also affect the dust capture performance of a system because of reduced air volume if increased resistance is not accounted for in setting the fan static. Other negative effects of reduced airflow rates can include, but are not limited to: material buildup on duct system surfaces, collector internal surfaces and increased system maintenance.

- Many materials used to construct filters can become weaker when they become saturated, and in extreme cases, the filter media can begin falling apart. As an example, filter media using cellulose (paper) substrate will lose much of its strength when it gets wet. The filter can then be damaged during pulse cleaning.

In addition to the water issues with filters and dusts, water in compressed air lines could create ice in the pulse valves, locking them into position in colder climates. Valves frozen in the open position consume excess compressed air, which adds costs to the operation without cleaning the filters. Valves frozen in the closed position will compromise pulse cleaning and reduce filter life. Either way, filters will not be pulse cleaned effectively, resulting in higher pressure drop and diminished system performance. Needless to say, it is important to ensure the compressed air is clean and dry. There are several steps to accomplish this. First, a compressor should be followed by an air dryer, of which there are two types of dryers in use in industrial settings – Refrigerant and Desiccant.

REFRIGERANT DRYER

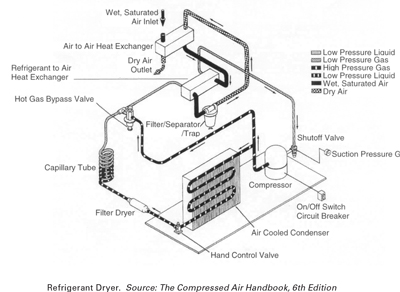

A refrigerant dryer works along the same principle as a home dehumidifier. The temperature of the compressed air is lowered with a heat exchanger coupled to a refrigerant loop. Due to this cooling, moisture condenses from the compressed air and can be drained from the line thus drying the compressed air. This type of dryer is typically capable of dropping the dew point of compressed air to between 35° to 40°F.

A refrigerant dryer works along the same principle as a home dehumidifier. The temperature of the compressed air is lowered with a heat exchanger coupled to a refrigerant loop. Due to this cooling, moisture condenses from the compressed air and can be drained from the line thus drying the compressed air. This type of dryer is typically capable of dropping the dew point of compressed air to between 35° to 40°F.

As long as the dust collector will be in an environment above 35°F to 40°F, the compressed air supply line should not see additional condensation, and a refrigerant dryer should be sufficient to protect the dust collector. However, if the collector is going to be exposed to temperatures below 35°F to 40°F degrees, harmful condensation can appear in the compressed air lines downstream of the refrigerant dryer. For this reason, a desiccant dryer may be required in climates that regularly see temperatures below 40°F.

It is important to protect the dryer from condensed water or oil emulsions by using a coalescing filter before the dryer. If the oil aerosols were allowed to enter the dryer, the evaporator heat exchanger tubing would quickly become coated and lose its flow and cooling abilities. Since the dryer will produce condensation through cooling, there is generally a cyclone separator at the dryer outlet.

DESICCANT DRYER

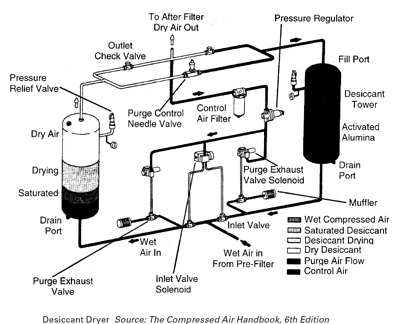

As the name implies, desiccant dryers use desiccants to dry compressed air. The desiccant adsorbs the moisture (rather than absorbs). This means the moisture adheres to the desiccant, but the desiccant material itself does not change. Because of this, a desiccant can be purged of the moisture and reused. Most desiccant dryers have two containers of desiccant.

As the name implies, desiccant dryers use desiccants to dry compressed air. The desiccant adsorbs the moisture (rather than absorbs). This means the moisture adheres to the desiccant, but the desiccant material itself does not change. Because of this, a desiccant can be purged of the moisture and reused. Most desiccant dryers have two containers of desiccant.

When one container has reached its moisture capacity, valves shift so it can begin to be purged of moisture while the second container of desiccant is put into use. The big advantage of desiccant dryers is a dewpoint of – 40° F or lower thus allowing the compressed air to be used in sub-freezing conditions without the issues of continued condensation and freezing.

POINT OF USE CONTROL AND FILTRATION

Once compressed air leaves the dryer, some air management needs to be done before it reaches the dust collector. First, the pressure of the compressed air needs to be regulated so the collector is supplied with compressed air that meets the manufacturer’s specifications. Consult your collector manual for compressed air requirements for the dust collector. This is very important, as pulse cleaning with compressed air higher than the manufacturer’s recommendations can result in collector or filter damage. Therefore, a pressure regulator with gauge should be installed right next to the dust collector.

Next, a shut-off/lock-out valve should be installed so compressed air to the collector can be shut-off and locked-out prior to maintenance being performed on the collector.

Next, a shut-off/lock-out valve should be installed so compressed air to the collector can be shut-off and locked-out prior to maintenance being performed on the collector.

Lastly, an automatic condensate valve and particulate filter should be installed before the collector to capture any remaining dust or condensation that may have been generated in the piping between the dryer and the dust collector.

It should be noted that all point-of-use compressed air management devices mentioned in this section can be taken care of with one device that combines the regulator, gauge, shut-off/lock-out and final filtration.

In summary, compressed air is a critical utility for many industrial dust collection systems. By managing compressed air usage and condition (clean, dry compressed air), costs and collector maintenance can be reduced.